Manual drive presses provide the operator with full control to precisely locate the clinch. Designed specifically for sheet metal fabricators, this is an economic alternative for clinching and short stroke pressing needs.

Key Specifications | |

|---|---|

Maximum Combined Material Thickness |

3.5 mm [Mild Steel] |

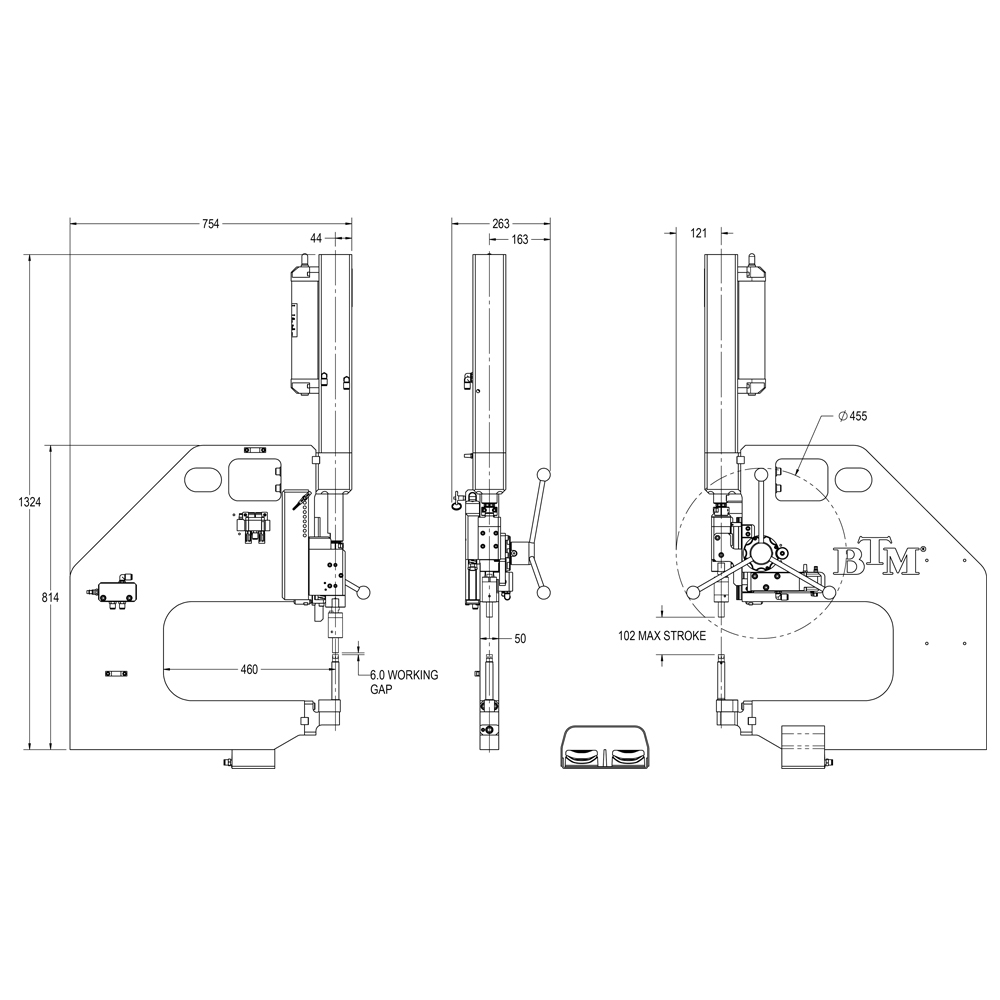

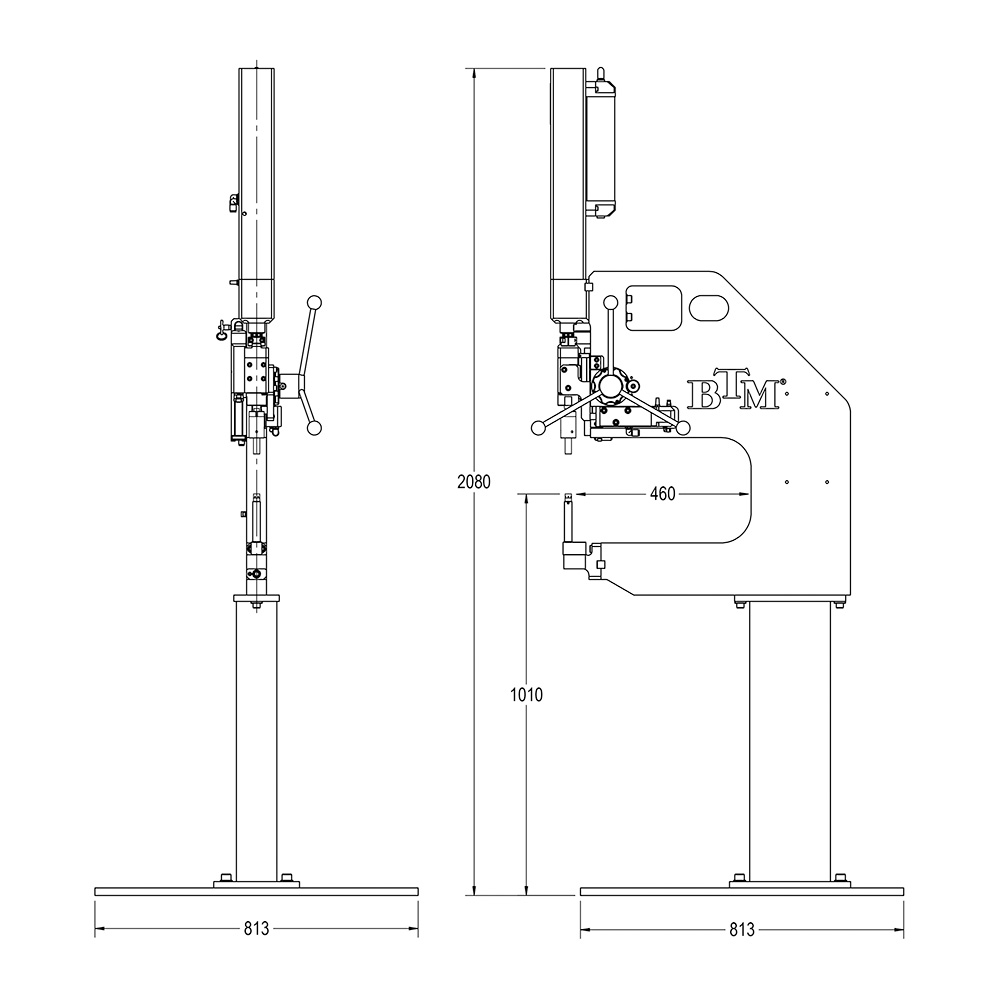

Throat Depth |

460 mm |

Maximum Stroke |

102 mm |

Cycle Time |

1 second |

Weight |

169 kg [372 lb] |

Standard Input Pressure |

5.5 BAR [80 PSI] |

Tool Size |

3.0 to 4.6 |