Clinch Tooling

Providing Customers with the Industry’s Broadest & Most Capable Clinching Tools.

100,000 styles, sizes, and combinations of BTM tooling, designed and engineered with premium tool steels and precision manufacturing to produce high integrity joints, long tool life and to accommodate material and processing variations.

Our application engineers work with you to select the optimal tooling and equipment. We ship 97% of standard tooling within 3 business days.

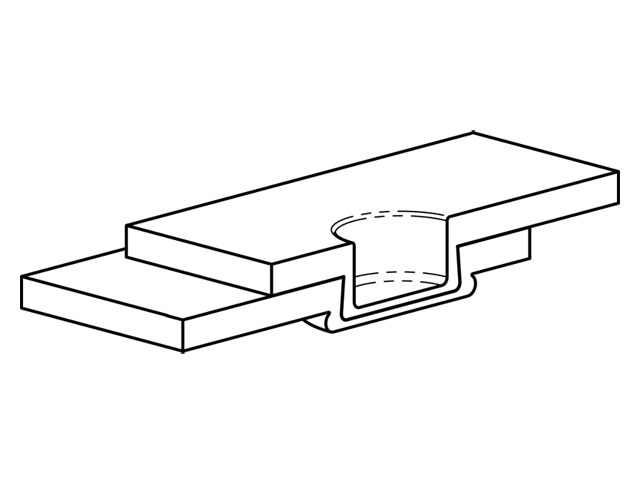

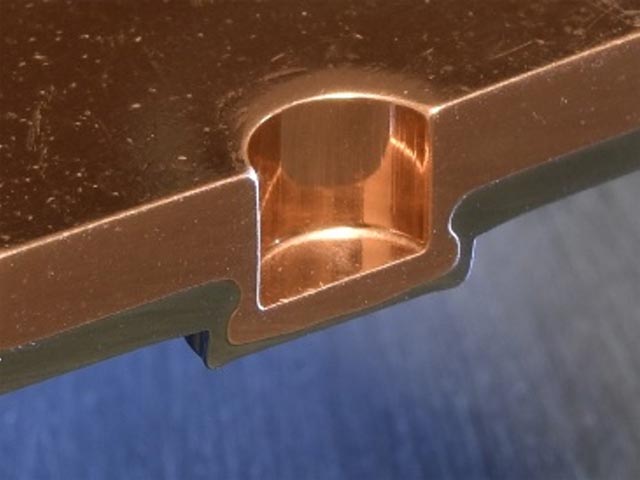

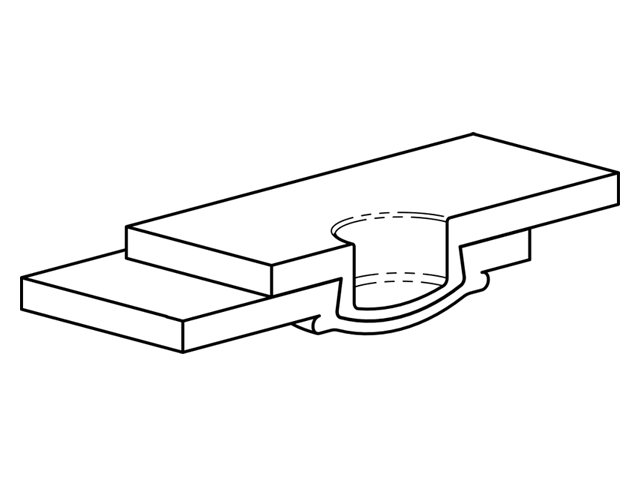

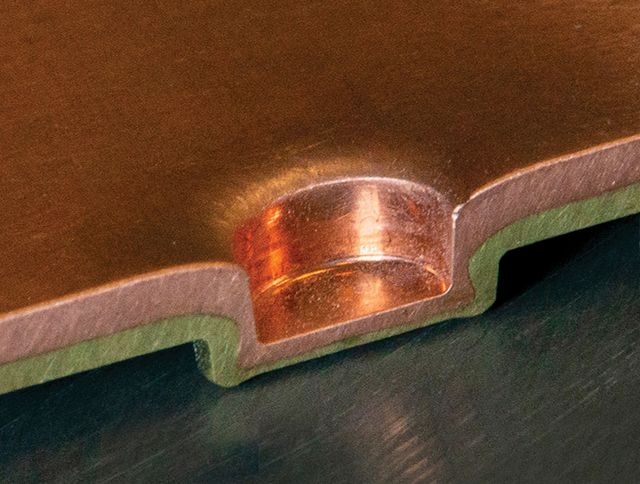

The majority of customer sheet metal joining needs can be met with Tog-L-Loc® tooling. Joints are strong, consistent, and highly fatigue resistant. The round joints are produced by cold forming layers of sheet metal between a punch & die that utilizes extensible die blades. Tog-L-Loc® tooling can be used to connect a wide range of sheet metals and/or profiles of different material types & thicknesses.

Tog-L-Loc® tooling has the broadest range of standard sizes, geometries and configurations. Special purpose variants of Tog-L-Loc® are included in the Special-Loc® and Custom-Loc® tooling families.

Joint Characteristics

- Non-Cutting

- Gas-Leak Proof

- High Stability

- Excellent Electrical Conductivity

- Fatigue Resistant

- 2 Layers Joints

- 3 Layers Joints with Certain Material Combinations

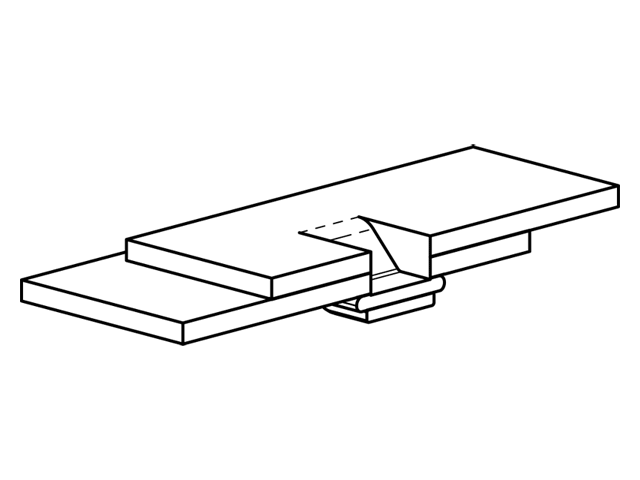

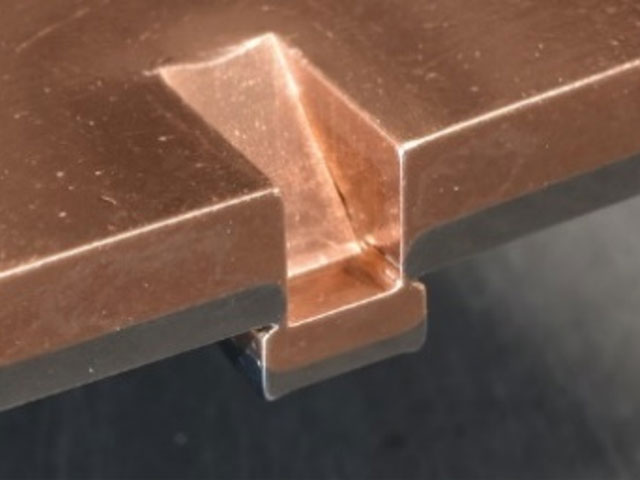

Lance-N-Loc® tooling uses extensible die blades with a rectangular punch that shears the sides of the joint. Like Oval-Loc®, the rectangular Lance-N-Loc® joints ensure part geometry is locked with a single joint (Geo-Clinch®). The shearing action allows Lance-N-Loc® to join hard metals (stainless) & metal to non-metal materials (gaskets, filter cloths), thick to thin and multiple layer combinations (5 layers for example). Joints are not gas-leak proof.

Joint Characteristics

- Cutting, Semi-Cutting

- Suitable for Multiple Layers

- Suitable for Combinations with Non-Metallic Partners

- Good for Thin-into-Thick Combinations

- Suitable for Stainless Steel

- Excellent Electrical Conductivity (“Grounding Joint”) Non-Twisting

V-Loc™ tapered punches & concave dies are for materials like aluminum, prone to galling and age hardening. Joints are strong, consistent, and highly fatigue resistant. Like Tog-L-Loc®, the round joints are produced by cold forming layers of sheet metal between a punch & die utilizing extensible die blades. V-Loc™ can be used to connect sheet metals and/or profiles of different material types and thicknesses.

Joint Characteristics

- Non-Cutting

- Gas-Leak Proof

- High Stability

- Excellent Electrical Conductivity

- Fatigue Resistant

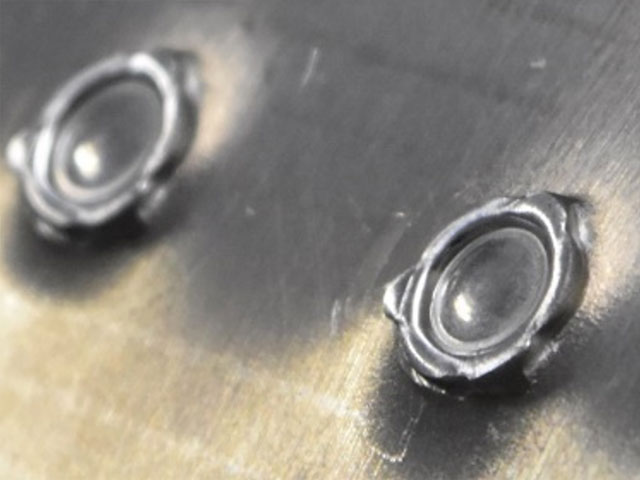

Oval-Loc® tooling is similar to Tog-L-Loc® tooling except it forms an oval joint. The oval shape ensures part geometry is locked with a single joint (Geo-Clinch®). It is ideal when a strong sealed joint is required in narrow spaces, like electrical terminal connection.

Oval-Loc® is also particularly suitable for the automotive industry where several components are pre-fixed in GEO stations. It is characterized by its compact, space-saving design and offers an excellent alternative to twin and multi-joint solutions.

Joint Characteristics

- Non-Cutting

- Gas-Leak Proof

- Space Saving

- High Torsional Moment – Good Torsional Safety

- Very Good Electrical Conductivity

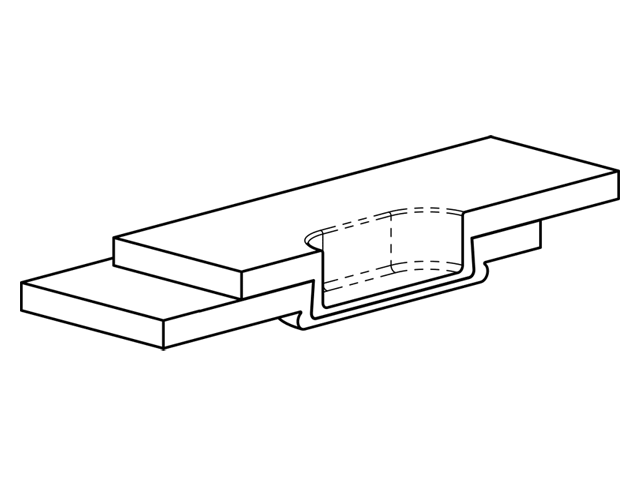

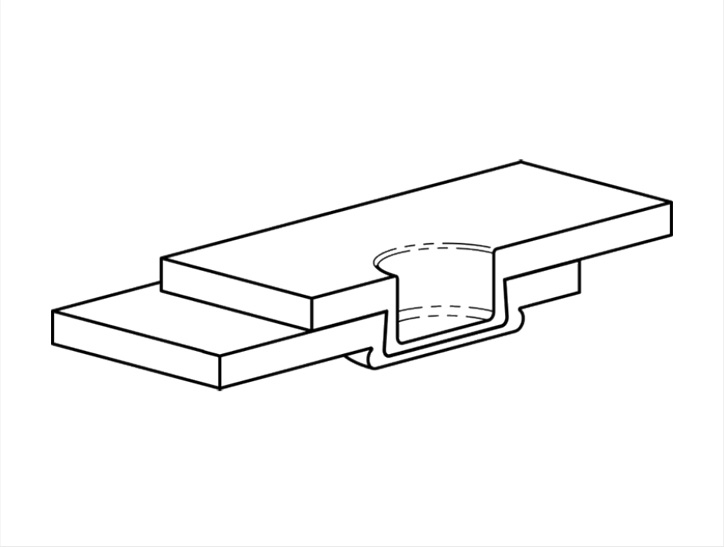

Fixed-Loc® uses a slim design die without moving blades to address forming joints in narrow flanges and channels. Like other BTM tooling families, round joints are produced by cold forming layers sheet metals between a punch & die. Stainless steels, as well as combinations of different material types and thicknesses, can be clinched with the Fixed-Loc®.

Joint Characteristics

- Non-Cutting

- Gas Leakproof

- For Narrow Channels

- For Narrow Flanges

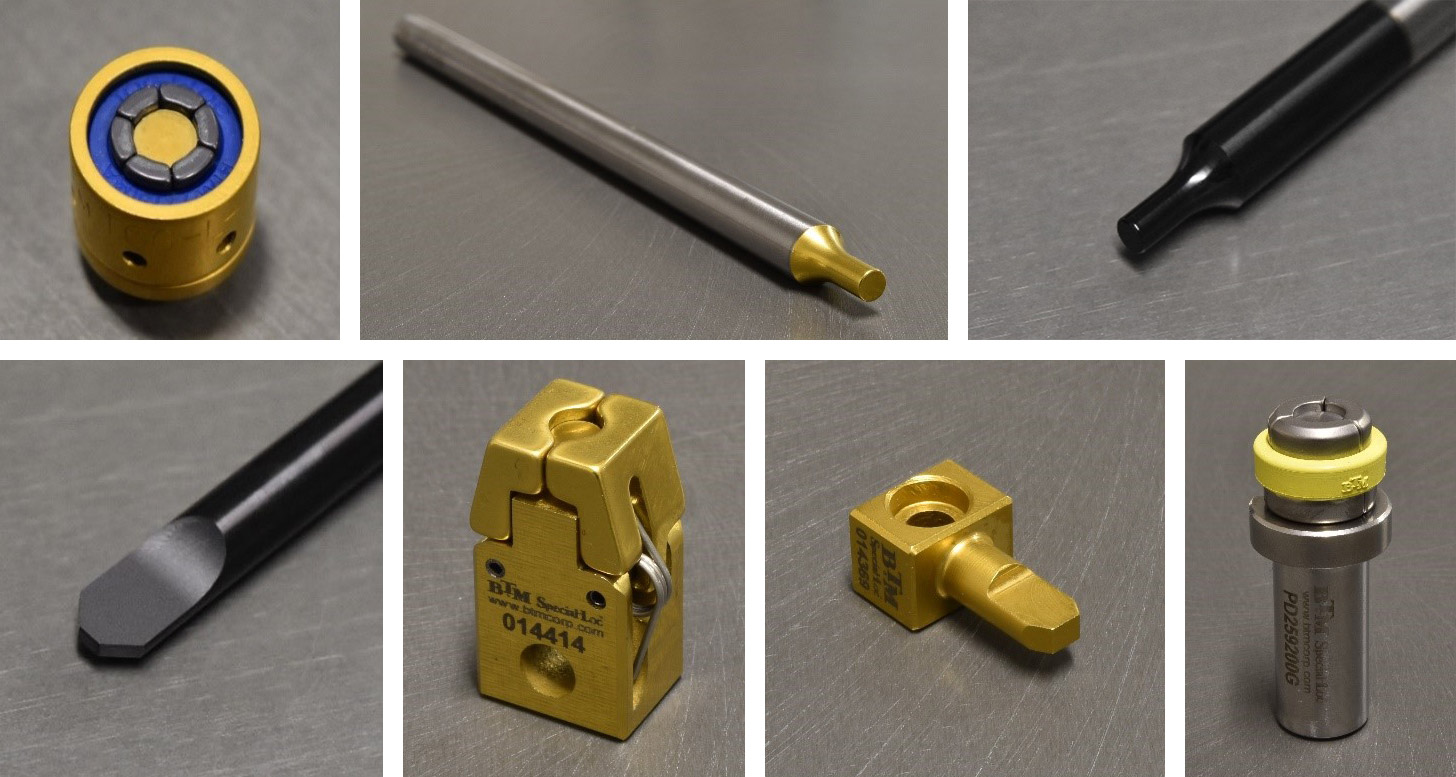

Special-Loc® is a modular family of tooling components used for difficult to join material combinations and difficult to access joining locations. The Special-Loc® family includes tooling engineered with exotic alloys, advanced coatings, and ultrafine finishes.

Custom-Loc® tooling is purpose-engineered to meet the requirements of the most challenging customer specific material joining combinations and the most difficult to reach joining locations.

Tool Holders & Accessories

Punch holders, die holders, stripper tips and die extensions ensure optimal tool performance.