Solutions

Solutions

Work Holding

Industry Leading

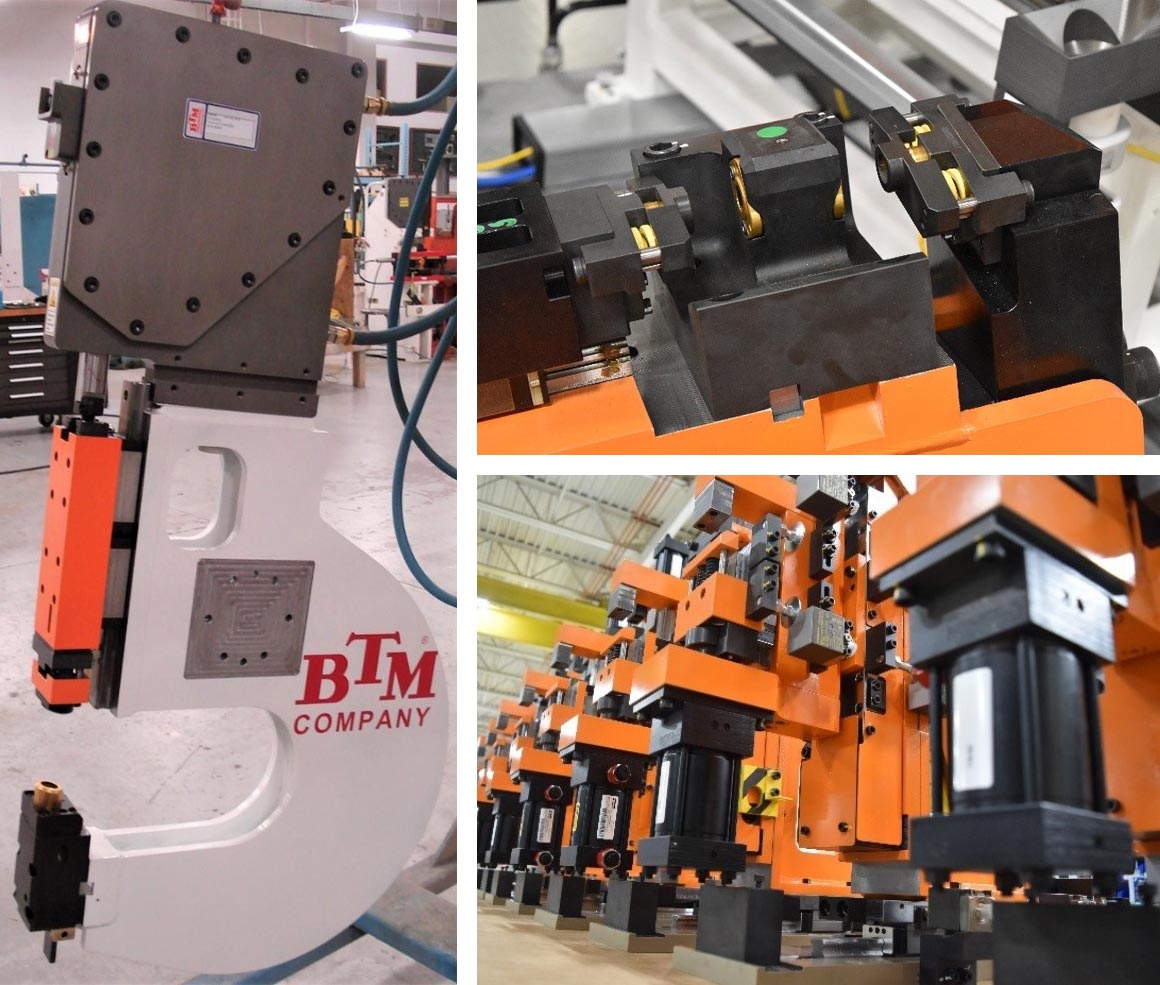

BTM designs and manufactures pin clamps, power clamps and grippers for small business and global corporations.

We provide customers with industry leading engineering and support to ensure your application requirements are achieved. BTM work holding equipment is designed, manufactured and serviced from Marysville, MI where our vertically integrated, flexible manufacturing operations deliver standard and custom equipment in world class delivery times.

Weld/Harsh Environment

Heavy duty clamps are precision machined from a single piece of aircraft grade aluminum & hard coated for superior performance. BTM clamps are tough, durable and resist corrosion and contamination.

Heavy Duty Pin Clamps

Heavy Duty Power Clamps

TPCA adjustable arm opening sealed precision power clamps are ideal for a range of industrial applications.

Robot End-Effector

For end-of-arm tooling and overhead part transfer applications where fail-safe locking is essential.

General Use

Reliable, durable and cost-effective work holding equipment is ideal for general use.

Regular Duty Power Clamps

Light Duty

Compact size with flexible pin, arm and gripper configurations are ideal for light duty industrial use.

Pin Clamps

Power Clamps

Presses & Press Units

BTM designs and builds press equipment for manufacturers, machine builders and systems integrators. BTM products include standard, modular and custom-engineered pneumatic, air-over-oil, hydraulic and servo-electric presses, press components & press units, robot mounted presses, integrated tooling solutions and advanced process monitoring.

Our vertically integrated flexible operations and modular equipment designs make BTM a partner you can trust to provide a wide range robust press equipment in world class time.

Air Toggle Presses

Pneumatic press units are compact with a thin profile for small spaces or close stacking and easy mounting (any position). BTM has complete press units, press heads, front mount units, punch & button units with integrated anvils and special purpose units with long strokes, double rams or integrated frames. BTM sales can help you choose the right press.

Pre-Engineered for Clinching & Piercing

Air-Over-Oil Cylinders

High force is created using a pneumatic cylinder as a pump for the hydraulic cylinder, up to 100 tons.

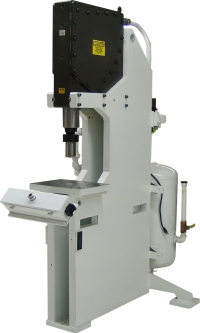

Floor & Bench Presses

Air Toggle Presses and Air-Over-Oil Presses in floor and bench frames are available for your sheet metal application.

Hydraulic Press Units

BTM Hydraulic Presses are for demanding applications.

Modular C & D Press Frames

C & D Press Frames are available in modular and custom designs for integration with other equipment.

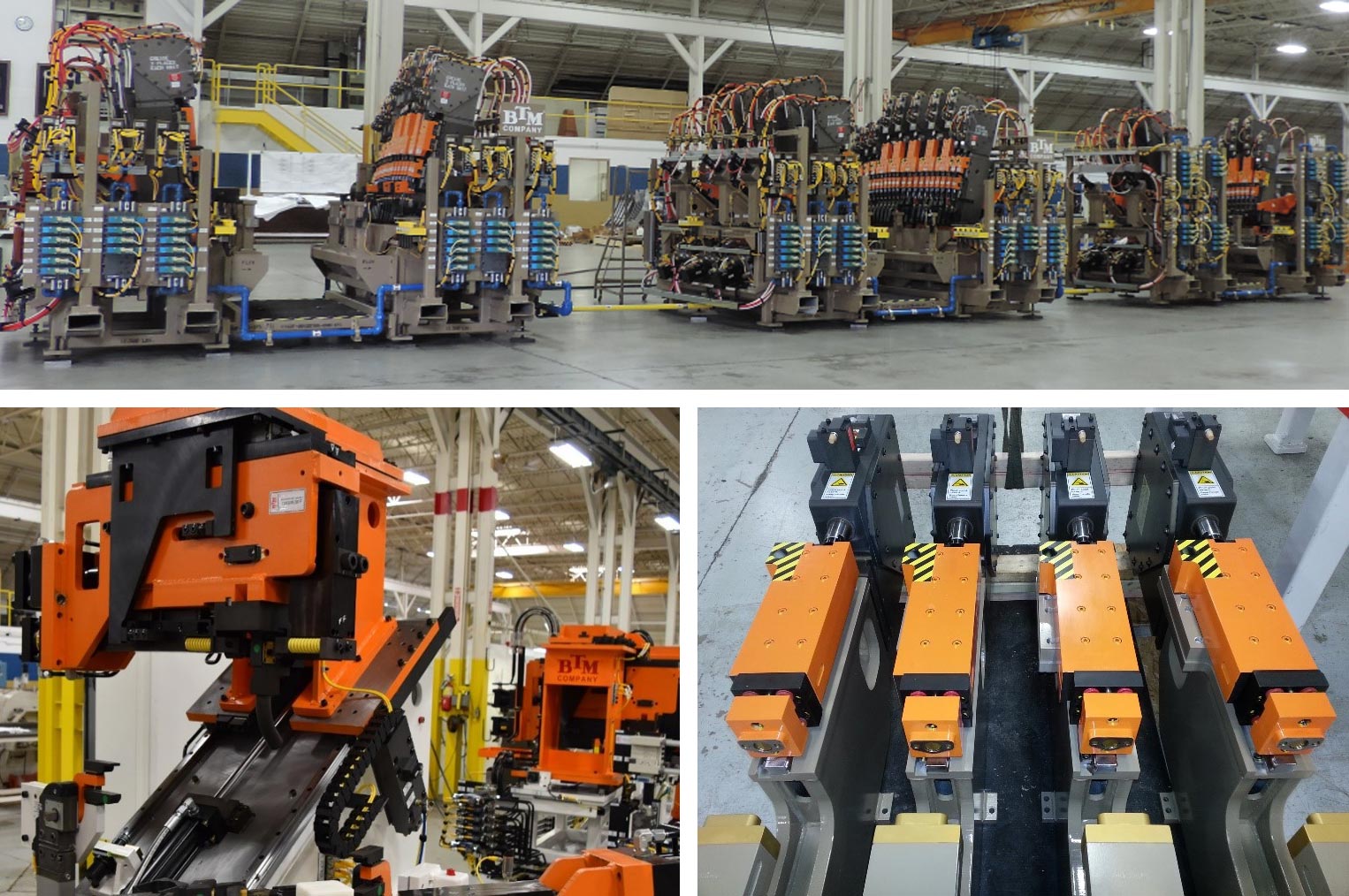

Special Machines & Custom Systems

From single station presses to fully automated assembly systems, BTM has proven solutions for the sheet metal industry.

Piercing and Forming Equipment

BTM has tooling, manual equipment, modular and automated systems for piercing, forming, swaging, shearing, notching, coining and other applications for system integrators, OEM’s and component suppliers.

Our Piercing equipment solutions include engine cradles, car and truck frames, hinges, A-Class surfaces, shock towers and bumpers. Each new project benefits from our experience with tooling & equipment packages for hundreds of sheet metal assembly & manufacturing applications

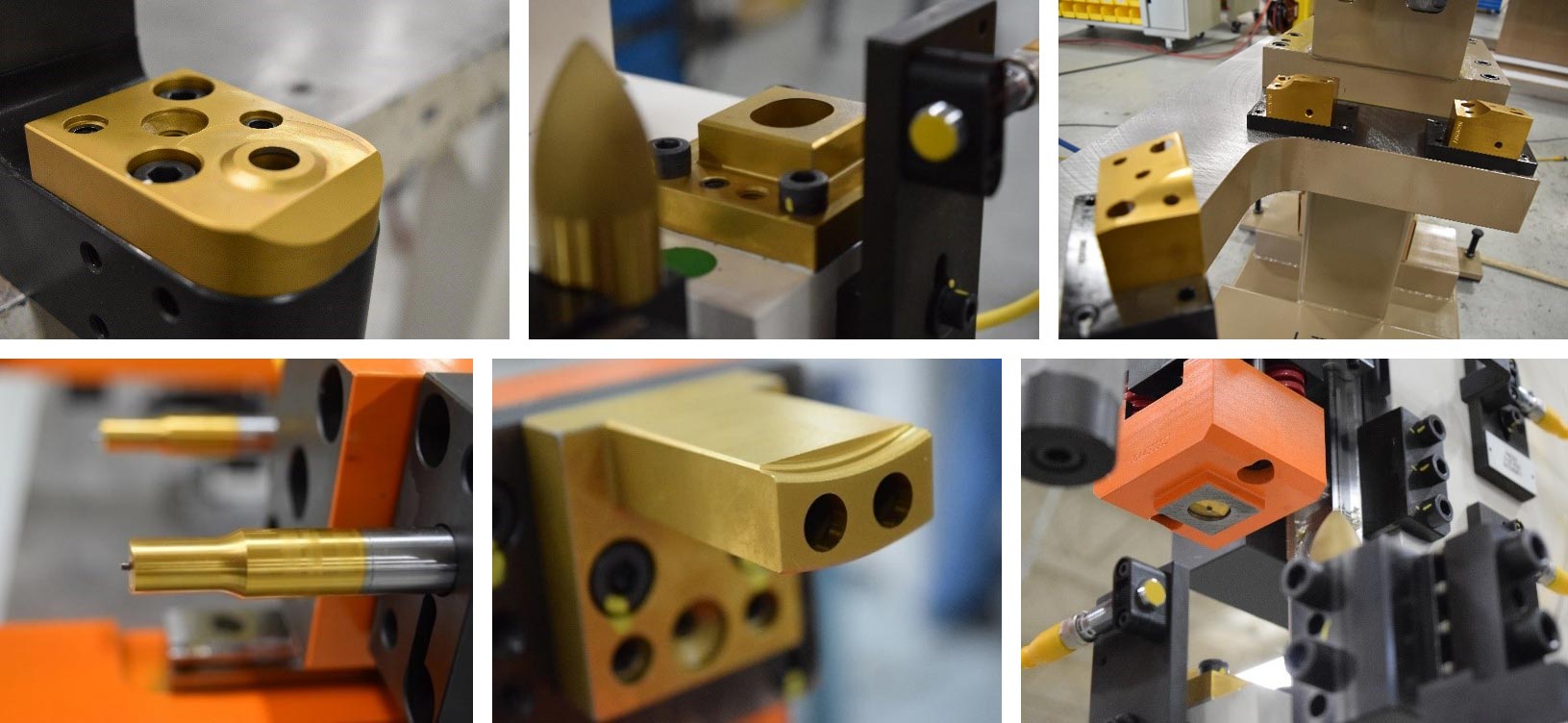

Custom & Replacement Tooling

Benefit from our experience with custom tooling, complex geometries, exotic materials, advanced coatings and ultra-fine finishes. BTM in-house tooling designers and vertically integrated tool and die manufacturing ensures single point accountability for first-set and replacement tooling needs. BTM also provides build-to-print replacement pierce tooling.

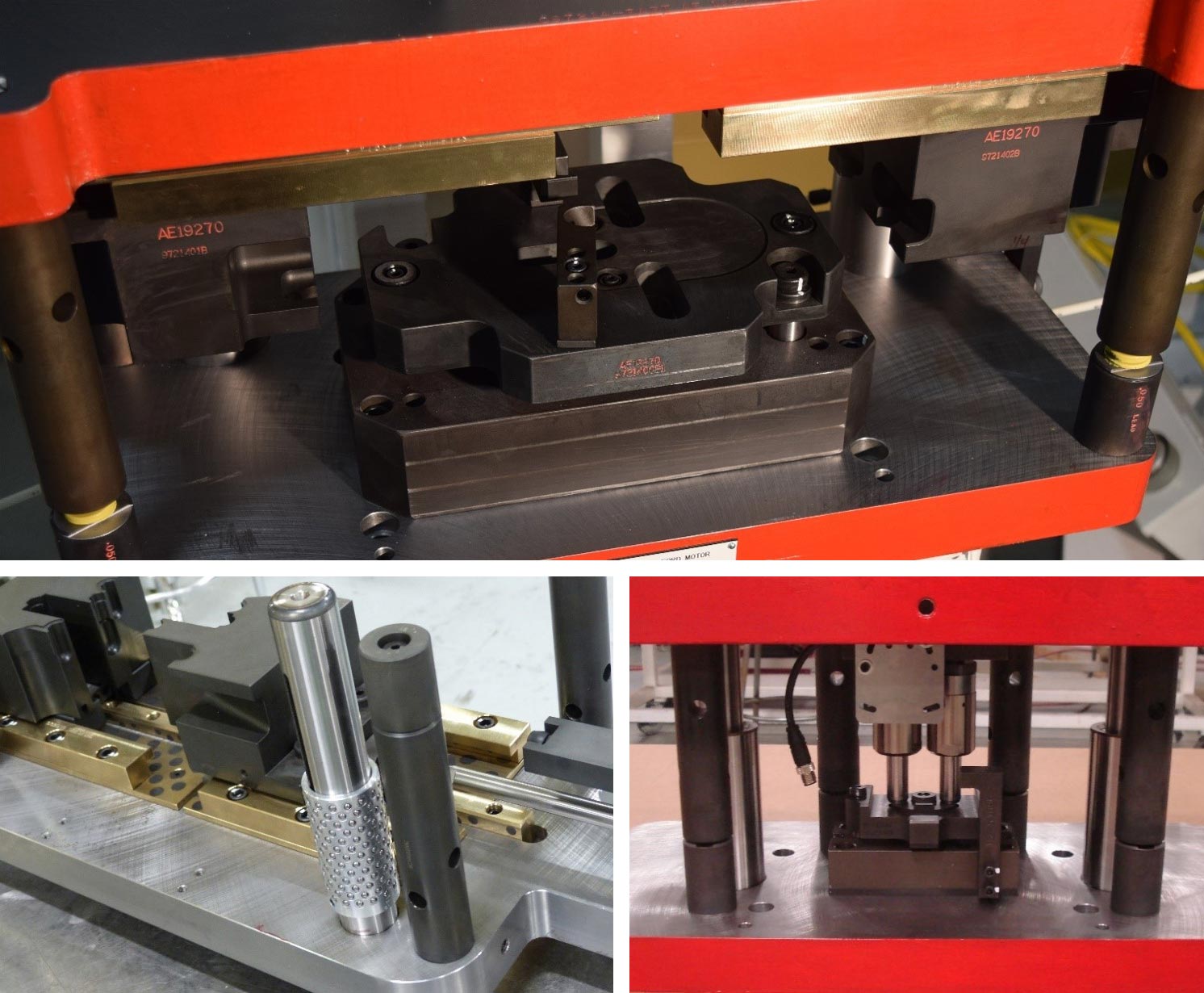

Die Sets

Piercing, forming and swaging die sets for single or multiple tooling combinations can be combined with BTM high force presses or integrated with your equipment.

Press Units

BTM designs piercing solutions using our standard or custom press units with high force frames and pneumatic, hydraulic, air over oil or servo-electric power.

Operator Workstations

Workstations are designed to maximize productivity with operator comfort and safety.

Robotic Piercing Stations

Robotic stations for piercing applications and end-of-arm piercing units with BTM press units, integrated with your robotic equipment or a fully integrated robotic piercing work cell.

Special Machines & Custom Systems

BTM works in partnership with each customer to design and build special equipment that is right for the application, improves productivity and reduces production costs.

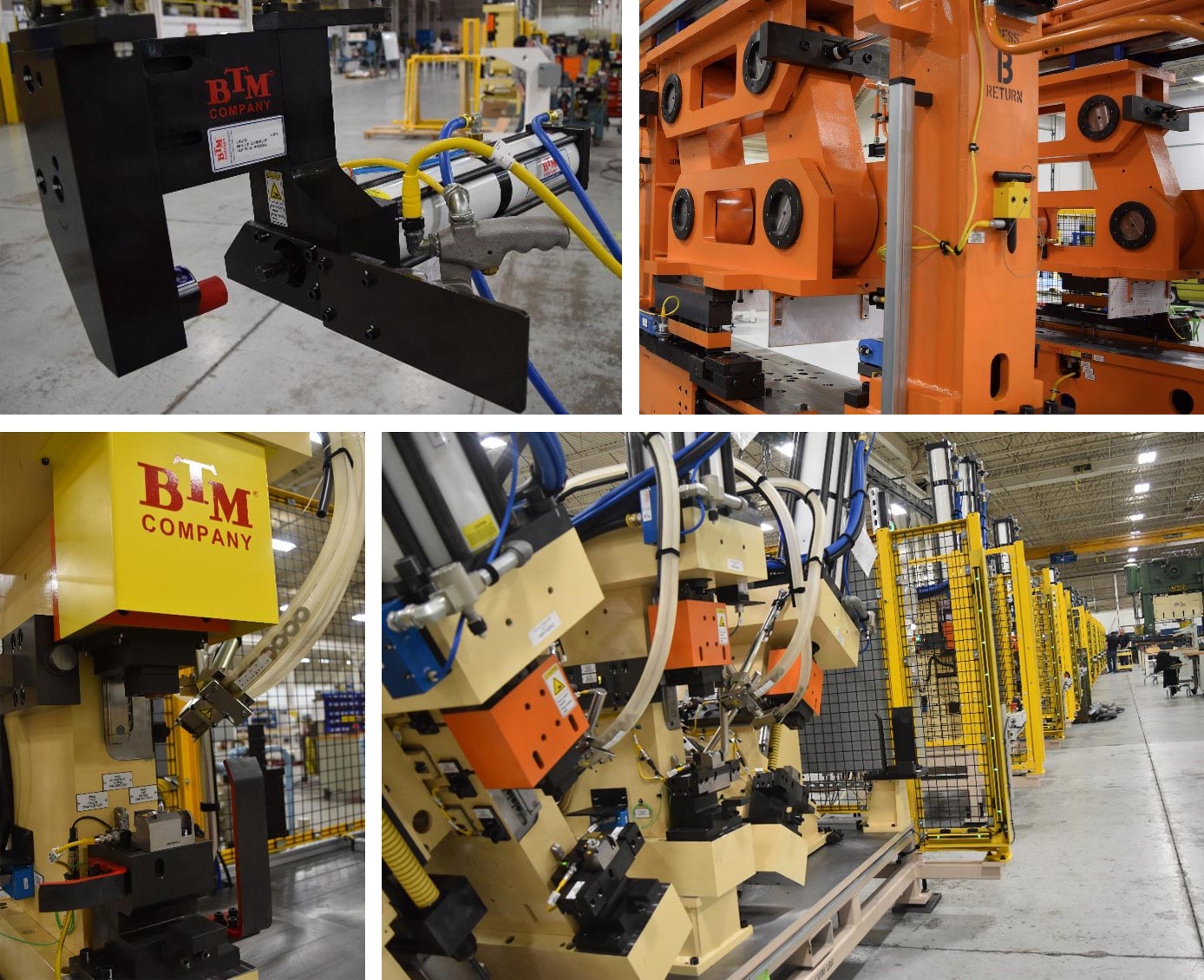

Fastener Equipment

Our strong working relationships with automotive-grade mechanical inserted fastener suppliers combined with our Modular Press Architecture and automation expertise ensures your equipment is fit to purpose and reliable. We deliver proven solutions to standard and custom applications including equipment for inserting multiple fasteners simultaneously, high speed applications, high force applications and applications that combine inserting fasteners with piercing and other operations.

Operator Workstations

Workstations are designed to maximize productivity with operator comfort and safety.

Robotic Work Cells

BTM provides press units optimized for use in robotic work cells and fully integrated robotic work cells.

Special Machines and Custom Systems

BTM leverages our relationships with automotive-grade mechanical inserted fastener suppliers to design and build special equipment for demanding customer applications.

Privacy Policy Statement

This online privacy policy applies only to information which is collected through our website, and not to information that is collected offline.

How to Contact Us

Our postal address is

300 Davis Road

Marysville, MI 48040

We can be reached via e-mail at This email address is being protected from spambots. You need JavaScript enabled to view it. or you can reach us by telephone at +1.810.364.4567.

What Information we Collect

For each visitor to our Web page, our Web server automatically recognizes the user's domain name and IP address, but not the e-mail address.

We collect aggregate information on what pages users access or visit, information volunteered by the user, such as survey information and/or site registrations. We also collect information about the users operating system and browser.

Cookies

We use cookies to record user-specific information on what pages users access or visit.

Cookies are also used to store the username and password of site registrations if the user opts to 'Remember my login'. Passwords are encrypted before they are stored in a cookie.

How we Will Use the Information we Collect

BTM Company, LLC. is the proprietary owner of all information collected on its website. We will not voluntarily distribute this information to unaffiliated third parties, but we retain the right to use this information at our discretion including (though but not limited to) establishing contact with you directly or through a subsidiary or affiliated third party. By using our website(s), you consent to the collection and use of such information by BTM Company, LLC..

Changes to the Privacy Policy

We reserve the right to change our privacy policy without notice. Any changes will appear on this page.

Protecting Your Privacy

If at any time you wish to remove your information from our records, you may contact us at the above addresses or phone number.

If you feel that this site is not following its stated information policy, you may contact us at the above addresses or phone number.

Reporting Content

To report unacceptable content, contact the Marketing Department at This email address is being protected from spambots. You need JavaScript enabled to view it. with the date of post, company site where the post appears, name of the person posting, and the content posted.