Industry Solutions

Diverse Products for Diverse Markets

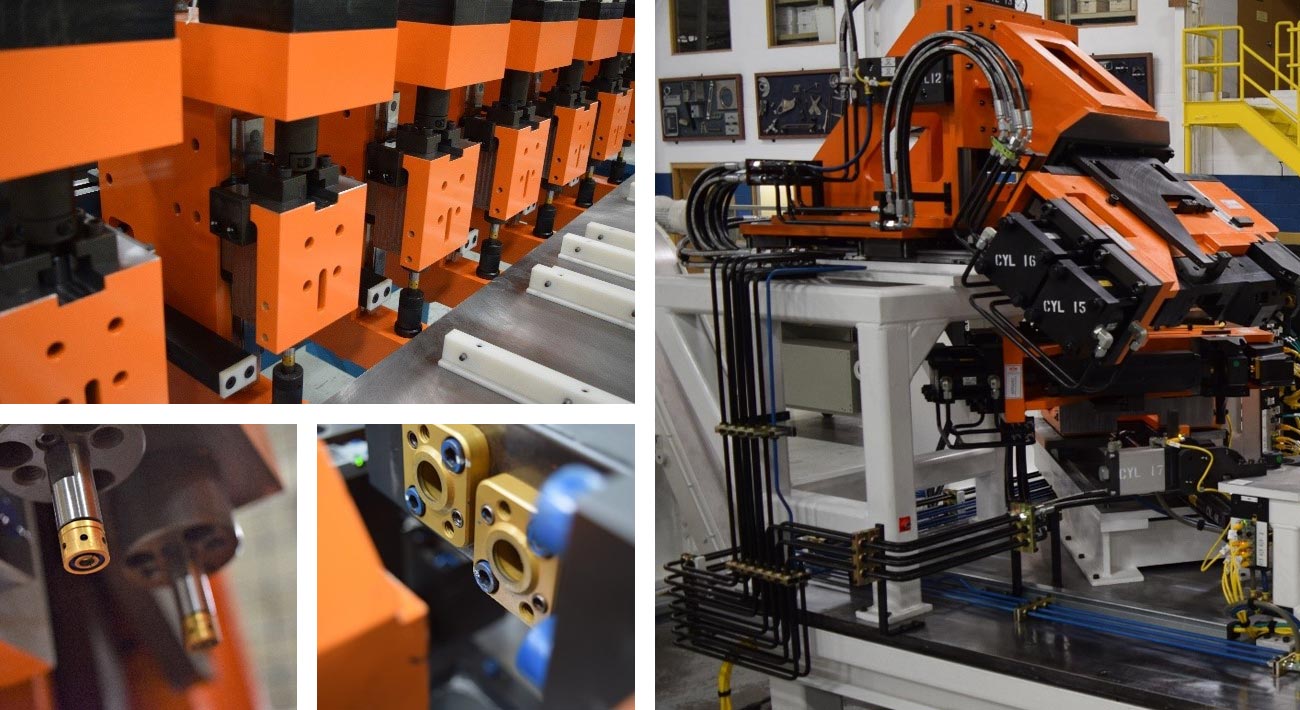

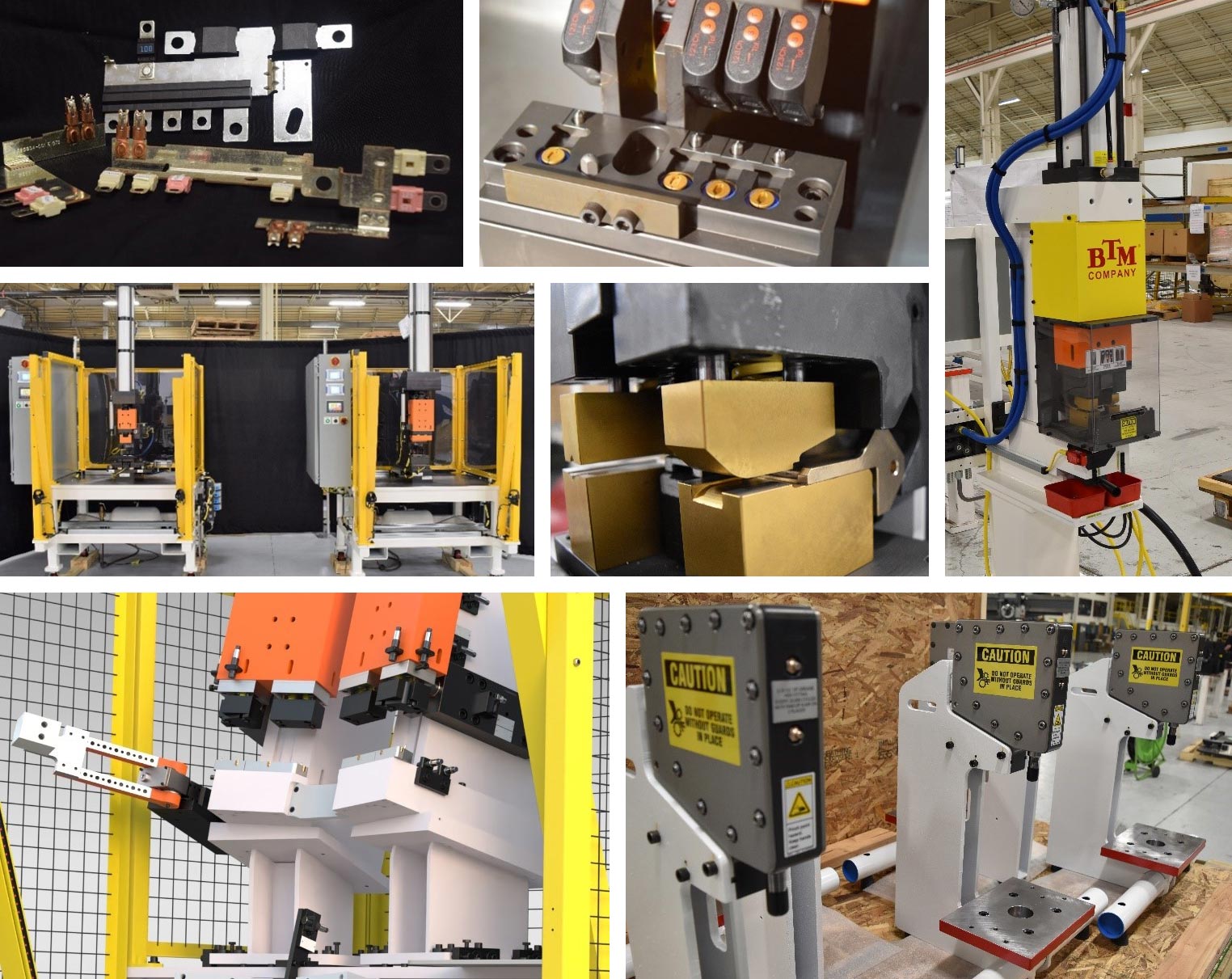

Engineered solutions with BTM standard, modular and industry focused sheet metal production equipment and tooling for Clinching, Piercing, Shearing, Bending, Forming, Coining, Tabbing, Mechanical Fastener Insertion and Work Holding. With over 20,000 equipment and tooling designs, BTM has a solution for you.

Automotive

BTM offers equipment and tooling solutions for the automotive industry.

- Engine Cradle Piercing

- Truck Frame Piercing

- Hinge Piercing

- Shock Tower Piercing

- Bumper Piercing

- A-Class Surface Post Piercing

- Battery Tray Piercing

- Plastic Component Piercing

- Servo Piercing

- Body Panel Clinching

- Structural Clinching

- Component Clinching

- Fuse Box Connections Clinching

- Heat Shield Clinching

- Moon Roof Clinching

- Mechanical Fastener Insertion

- Bushing Insertion

- Servo Clinching

- Pin Clamps

- Power Clamps

- Pin Locators

- Part Locating & Holding

- Door Trim Shearing

- Strap Shears

- Crush Can Shears

- Conical Forming

- Swaging Dies

Appliance

Equipment and tooling for appliance assembly and manufacturing.

- Dishwasher Frames

- Refrigerator Frames

- Washing Machine Frames

- Servo Clinching

- Oven Frames & Drawers

- Microwave Oven Housings

- Transmission Housings

- Plastic Component Piercing

- AC Frames & Components

- Water Heater Burner Units

- Furnace Frames

- Furnace Burner Units

HVAC

Floor presses, hand-held clinch presses, die sets, production fixtures and custom machines for high-volume sheet metal joining and forming.

- Ducts

- Vents

- Louvers

- Fans

- Housings

- Heating Systems

- AC Systems

- Refrigeration Systems

- Clamps

- Plenum Boxes

- Filter Frames

- Filter Housings

Construction

BTM has equipment and tooling systems for joining and forming sheet metal for building products and construction.

- Roofing Systems

- Garage & Entry Door

- Window Frames

- Door Frames

- Swimming Pools

- Lighting Fixtures

- Cable Tray Systems

- Mailboxes

- Structural Components

- Metal Framing Systems

- Furnaces

- AC Systems

- Water Heaters

- Channel Lettering

- Shelving Systems

- Cabinet Drawer Tracks

- Fireplaces

- Gas Burners

- Elevator Structures

Garage & Entry Doors

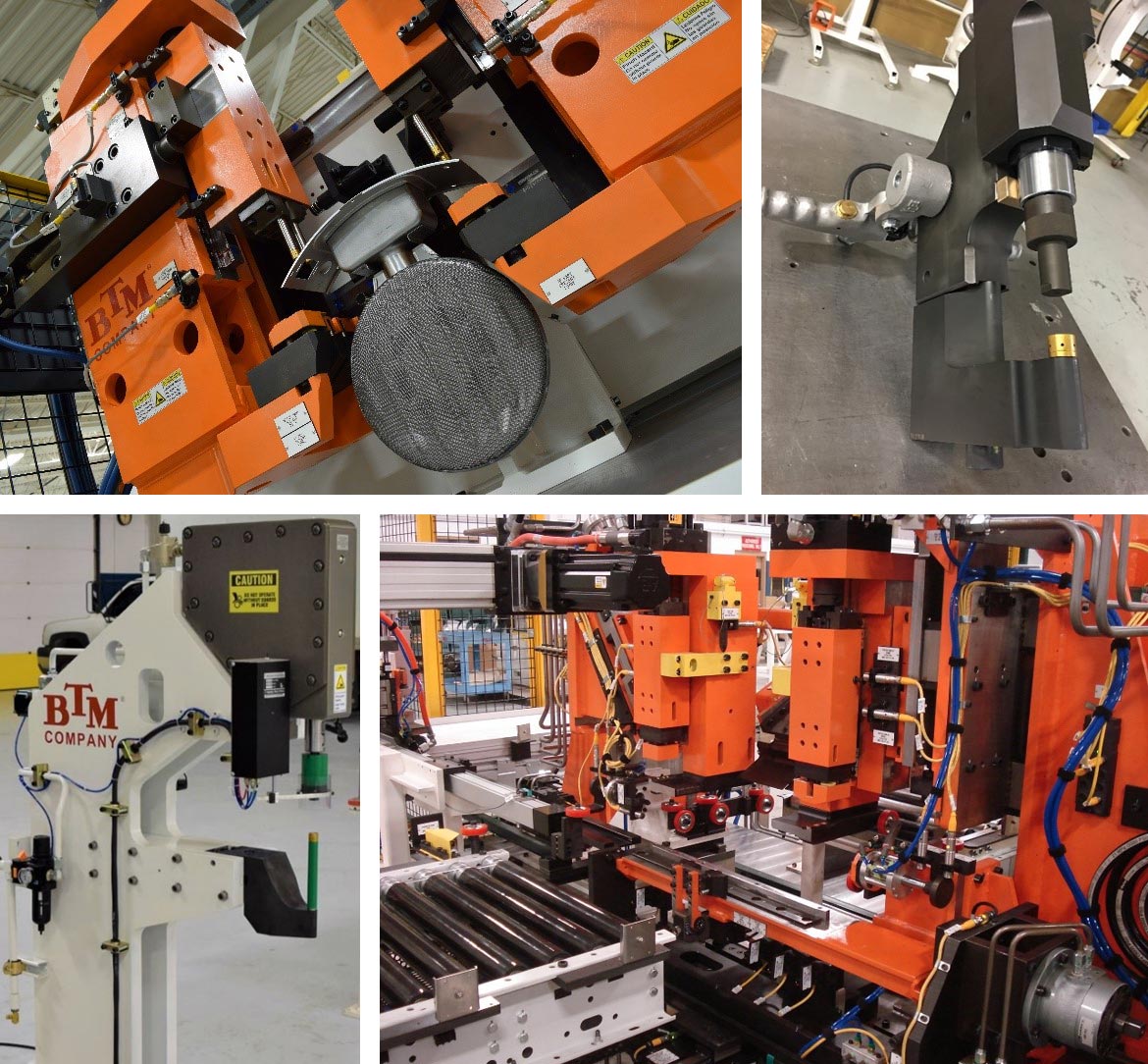

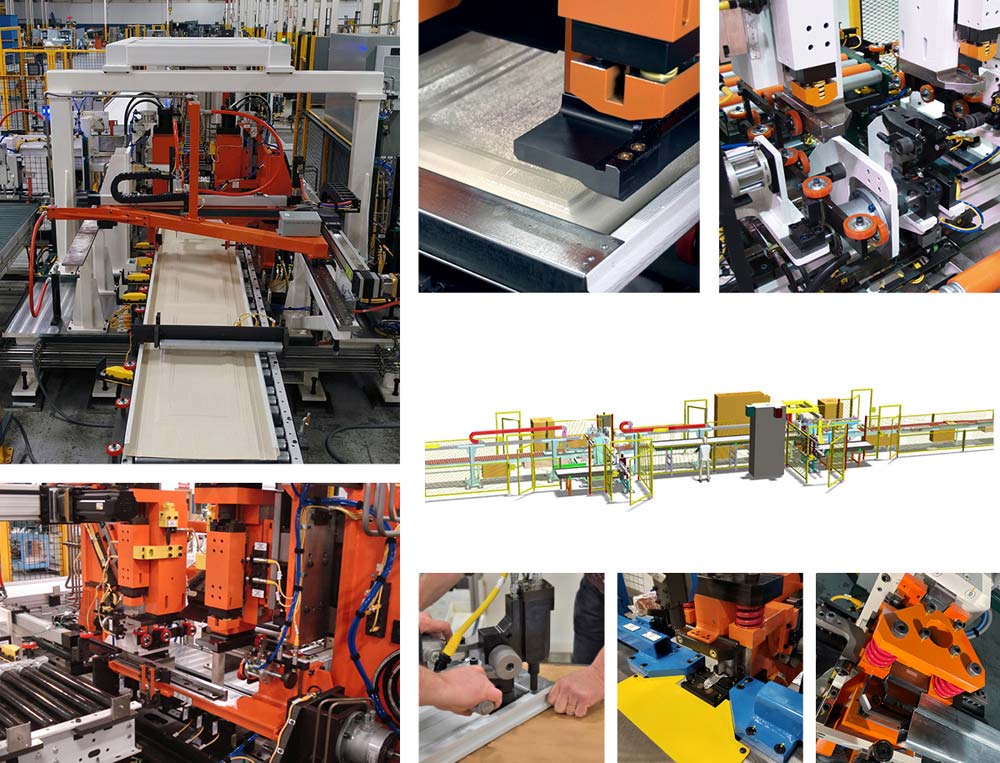

From high-speed automated stile attachment systems and production line integration to manual workstations and clinch tooling, BTM has been a garage door and roll up door production equipment leader since 1983. Residential and commercial door manufacturers trust BTM for engineering, equipment and tooling that delivers industry leading throughput, efficiency, up-time, and production flexibility. Whatever your requirements, BTM partners with customers to deliver optimal solutions and exceptional after-sales support.

- Garage Door Panels

- Produce & Install Stiles

- Install Stile Covers

- Apply Adhesives

- Install Astragal Retainers

- Pierce Holes

- Install Foam

- Produce & Install Hinge Plates

- Window Manufacture

- Packaging Lines

- Garage Door Guide Tracks

- Assemble Guide Tracks

- Attach Wing Clips & Mounting Plates

- Entry Doors

- Bending, Clinching & Piercing

- Flexible Solutions

- Panels Lengths from 2 foot to 30 foot

- Auto Changeover: Panel Widths, Length & Material Thicknesses

- Center, Single, Double, Triple End Stiles

- Robotic Applications

- Engineering & After-Sales Support

- Comprehensive System Integration

- New Station Integration in Existing Lines

- Production Optimization Analysis

- Conceptual Planning

- Open Controls Architectures

- Refurbishment & Upgrades

- Clinch Joint Testing

- Clinch Tooling Optimization

- Replacement Tooling

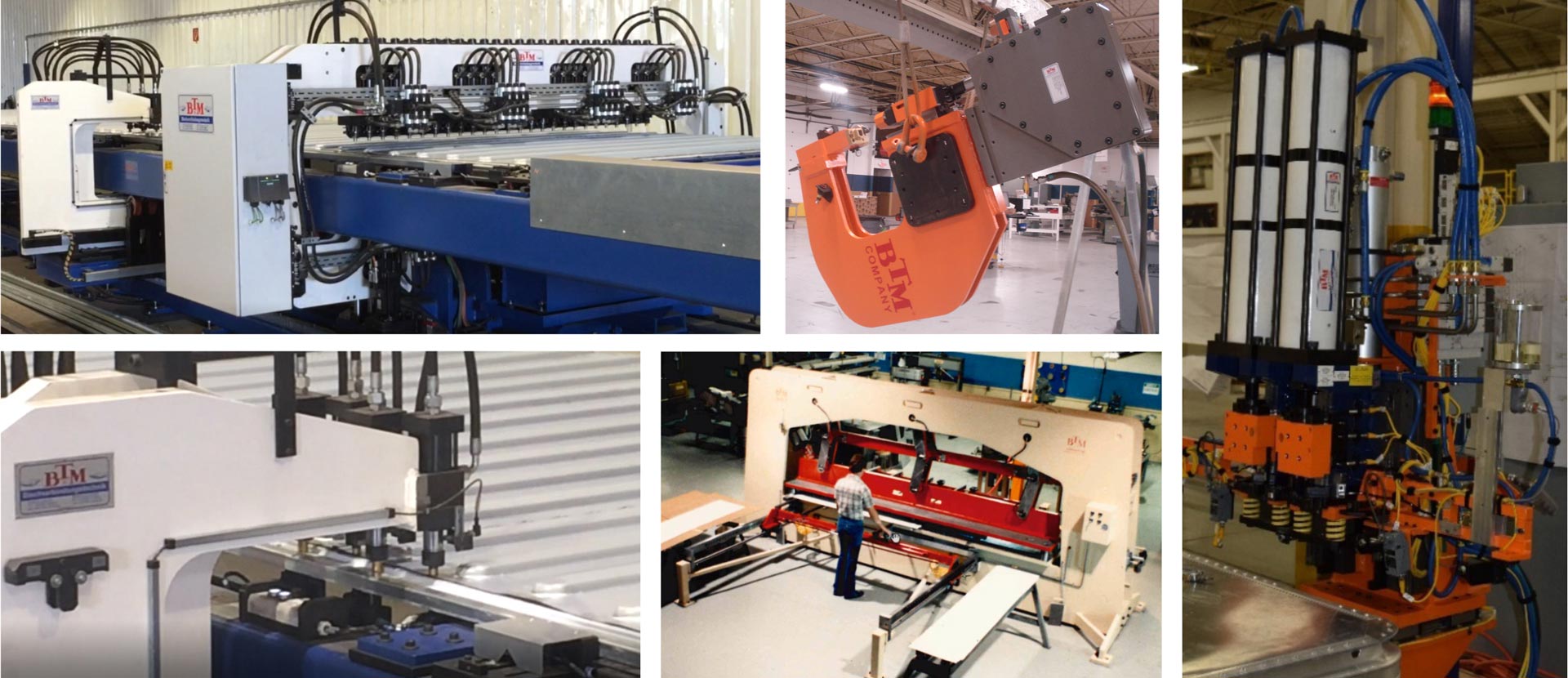

Semi-Trailer & RV

BTM has been providing engineered solutions to the semi-trailer, trailer and RV industries since the 1980s. From automated production cells to stand alone presses, BTM partners with OEMs and integrators to deliver world class manufacturing performance.

- Clinching

- Piercing

- Riveting

- Threaded Fasteners

- Adhesive Systems

- Advanced Automation

- Roof Attachment

- Side Panel to Top Rail

- Side Panel to Bottom Rail

- Bottom Rail To Frame Attachment

- Roof Bow Attachment

- Side Reinforcement Attachment

- Hinge Piercing

- Window Frame Assembly

- Door Hinge Clinching

- Air Handling Component Clinching

- Utility Truck Component Clinching

Electrical & Electronics

Oval-Loc™ tooling and equipment is the global leader for geometrically locked terminal joining and other electrical applications.

- Fuse Box Connections

- Terminal Connections

- Cable Trays

- Lighting Fixtures

- Electrical Panels

- Fan & Motor Housings

- Motor Chassis

- Battery Cables

- Fuses

Furniture

BTM designs and manufactures tooling, equipment and systems for sheet metal joining, forming and bending for the furniture industry.

- Drawers

- Cabinet Drawer Tracks

- Filing Cabinets

- Shelving Systems

- Cubical Components

- Structural Components

General Industry

BTM has standard products and creates custom solutions for sheet metal assembly and manufacture for a wide range of industries.

- Semi-Trailers

- Trailers

- Recreational Vehicles

- Inserted Fasteners for Heavy Equipment

- Hinge-To-Frame Attachment

- Filter Frames

- Sheet Metal Roll Joining

- Gas Burners

- Boatbuilding

- Metal Boxes

- Channel Lettering

- Structural Components

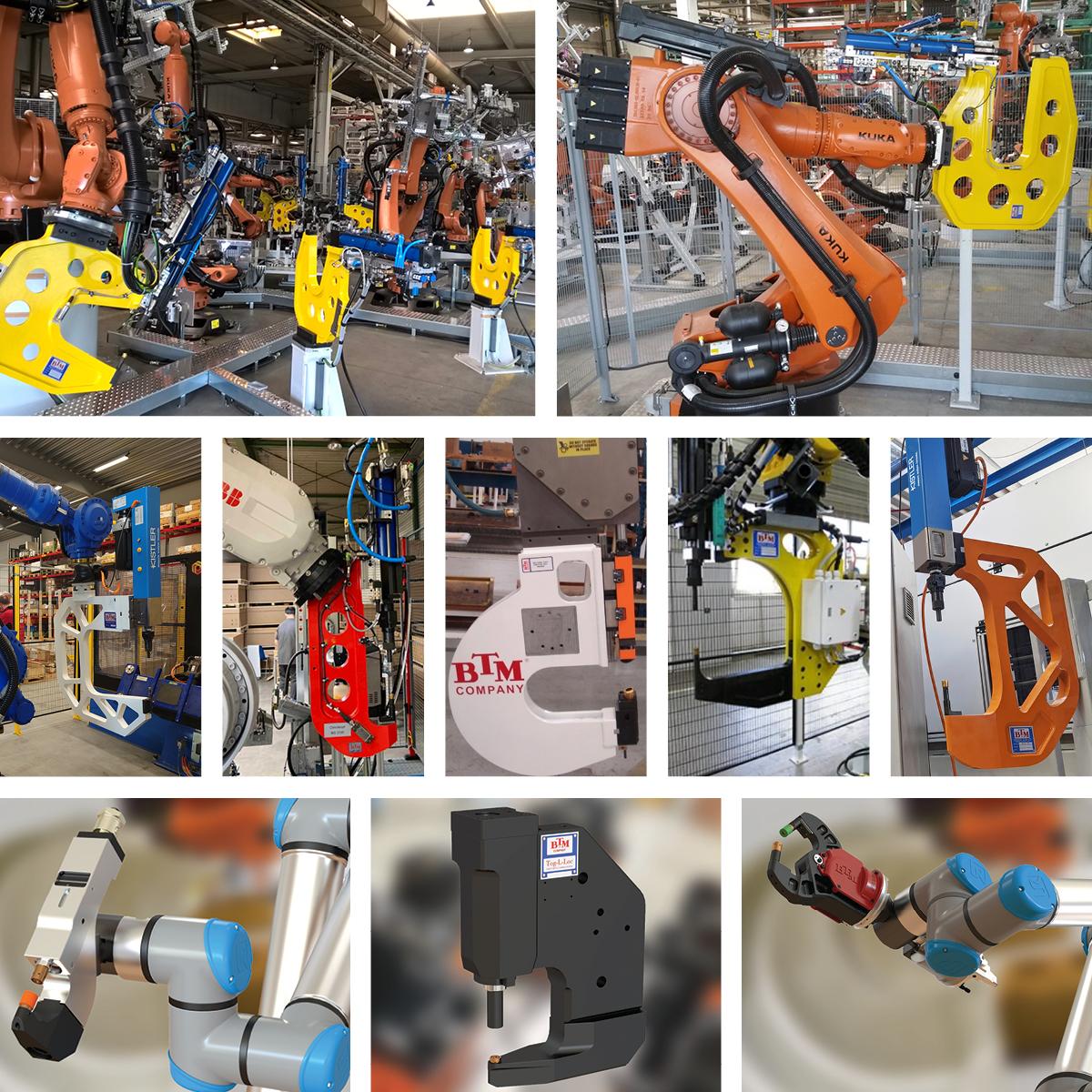

Robotic Integrators

Robotic systems integrators look to BTM for optimized robot-carried and robot-fed press units for clinching, piercing, riveting and mechanical fastener insertion. The BTM Modular Press Architecture meets needs that range from heavy-duty automotive work cells to light-duty cobot applications – it includes configurable and scalable pneumatic, air-over-oil, hydraulic and servo-electric power units that pair with standard & custom force frames to deliver solutions that minimize robot payload. BTM leverages our metallurgical lab and world class tooling, along with our performance monitoring expertise and aftersales support, to ensure production quality and throughput are unfailingly achieved. BTM pin clamps, power clamps and power grippers are ideal for robotic systems integrators who require industry leading engineering, technical performance and delivery timing.

- Forming Operation

- Clinching

- Piercing

- Inserted Fasteners

- Riveting

- Power Sources

- Servo-Electric

- Air-Over-Oil

- Pneumatic

- Hydraulic

- Force Frames

- Standard

- Spider

- Custom

- Adapted Hand-Held

- Work Holding

- Pin Clamps

- Power Clamps

- Power Grippers

Machine Builders & System Integrators

BTM industry leading engineering supports your special machine and systems integration needs for standard and custom solutions while our flexible manufacturing ensures world class delivery timing.